Introduction to Corrosion Resistance and Stainless Steel Types

Understanding "Which is more corrosion resistant?" is a critical consideration when choosing materials for industrial applications. Corrosion resistance impacts the longevity and efficiency of components, especially in demanding environments such as construction or aerospace. Among the most widely used materials, stainless steel stands out due to its durability and adaptability. However, even within stainless steel, there are variations that need to be analyzed closely, particularly 304 stainless steel versus 316 stainless steel.

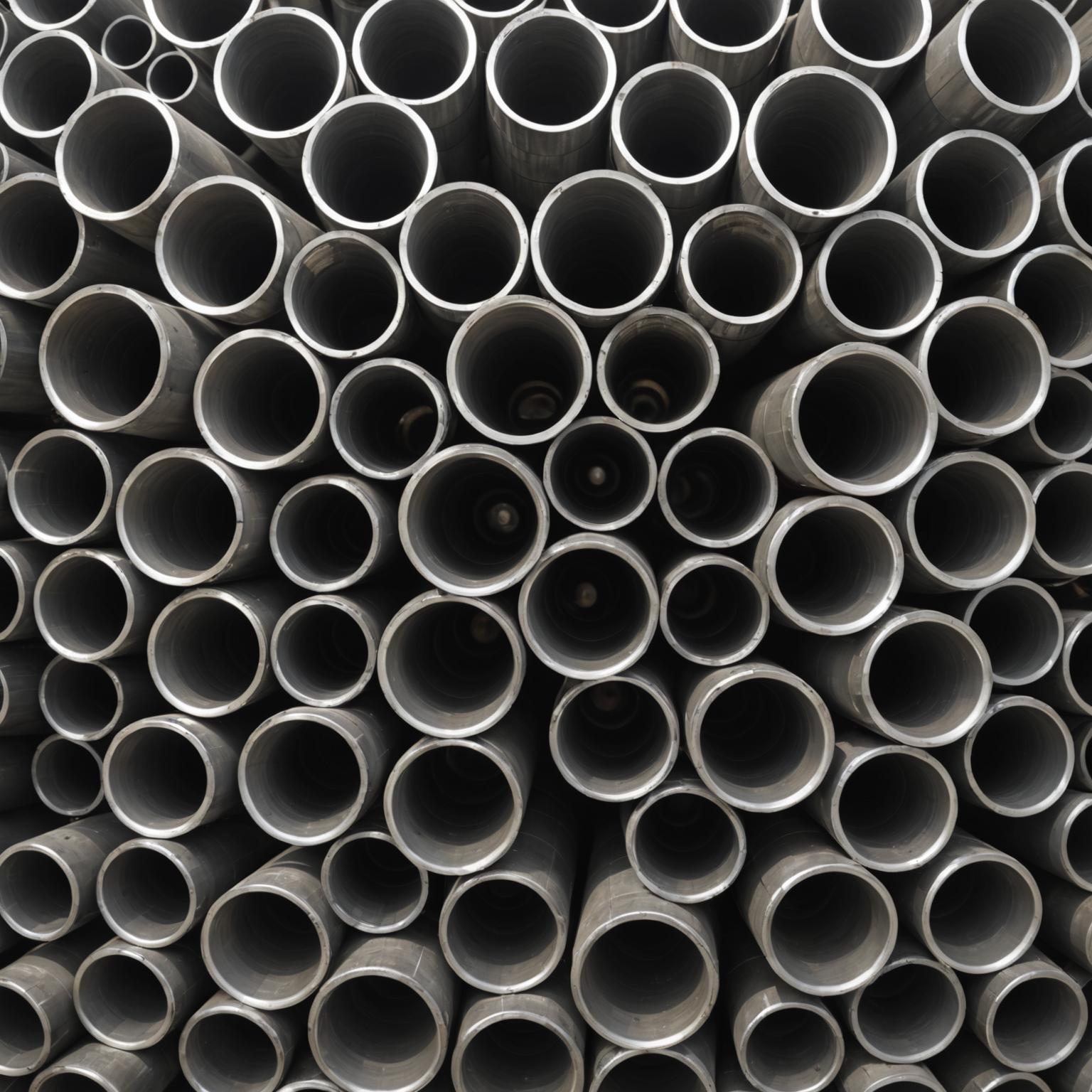

With advanced alloys like those used in stainless steel pipes, choosing the right grade involves balancing the cost, adaptability, and corrosion resistance. Both 304 and 316 stainless steel pipes find applications in various industries, but their unique properties make them suitable for different environments. In this comparison, we will explore whether 316 is better than 304 for corrosion resistance, and why it might matter for your specific projects.

Composition Makes the Difference

To understand the difference between 304 and 316 stainless steel tubing, it’s essential to begin with their compositions. Both alloys fall under the category of austenitic stainless steels, with high chromium and nickel content, which grant them excellent corrosion resistance and strength properties. However, 316 stainless steel contains an additional element: molybdenum.

The inclusion of molybdenum in 316 stainless steel enhances its corrosion resistance, particularly in environments containing chloride ions, such as saltwater or chemical processing facilities. This makes 316 the material of choice for marine applications, ensuring that the pipes remain rust-free even when exposed to harsh conditions. On the other hand, 304 stainless steel offers good corrosion resistance in mild environments but may struggle in areas with high chloride exposure.

This compositional difference significantly influences the performance of stainless steel pipes across industries. When selecting pipes for extreme conditions, the molybdenum content in 316 bridges the gap between versatility and resilience, making it more suitable for demanding applications. However, the choice always depends on the environment and cost considerations.

Performance in Corrosive Environments

When comparing 304 vs 316 stainless steel pipes, one of the most striking contrasts lies in how they perform in corrosive environments. For industries requiring extreme durability and longevity, corrosion resistance becomes pivotal. For example, businesses looking to invest in products like **High-Performance Alloy Tubes** benefit significantly from understanding this distinction.

304 stainless steel pipes excel in standard industrial applications, especially where exposure to moisture or air corrosion is limited. These are often seen as cost-effective and practical solutions for indoor frameworks, drinkable water systems, and architectural designs. Their polished surfaces and reliable tensile strength offer a balance of aesthetics and robustness.

Meanwhile, 316 stainless steel pipes dominate sectors such as marine engineering, chemical processing, and medical equipment manufacturing. The additional molybdenum in 316 ensures superior resistance against pitting and crevice corrosion, challenges that 304 stainless steel may struggle with in highly chlorinated or saline environments. This makes 316 ideal for saltwater piping systems, offshore construction, medical equipment frameworks, and other high-demand applications.

Cost vs Performance: A Key Decision Factor

While considering which stainless steel pipe to choose, cost undeniably plays a role. 304 stainless steel pipes are generally more affordable than 316 alternatives, making them attractive for budget-conscious projects. However, the initial cost should be weighed against the long-term benefits. Corrosion resistance directly impacts maintenance and replacement frequency, which can elevate overall project costs.

For projects where exposure to harsh chemicals or environmental extremes is rare, opting for 304 stainless steel tubes can lead to considerable savings without compromising quality. Moreover, products like **Premium-Grade Stainless Steel Tubing** based on 304 alloys feature sleek designs and precision engineering, making them ideal for aesthetically driven applications where corrosion risks are moderate.

On the flip side, industries demanding high-performance solutions should consider the investment in 316 stainless steel. Although the upfront cost is higher, the benefits of reduced maintenance, prolonged lifespan, and increased safety in aggressive environments outweigh initial expenses. For example, in aerospace or pharmaceutical industries, reliability under extreme conditions ensures better operation and fewer disruptions—a critical advantage given the stakes.

Versatility Across Industries

Both 304 and 316 stainless steel pipes offer incredible versatility, but their ideal applications differ based on environmental challenges and design requirements. Products like the **High-Performance Alloy Tubes** highlight the adaptability of stainless steel, unlocking endless possibilities for industries from construction to automotive.

Architectural frameworks frequently rely on 304 stainless steel tubing, leveraging its polished finish and lightweight properties for structural components that demand aesthetic appeal alongside strength. In medical and pharmaceutical fields, where sterility is crucial, 316 stainless steel often takes precedence, ensuring resistance against chemical cleaning solutions and contamination.

For industries such as oil and gas, particularly offshore platforms where salt exposure is high, 316 stainless steel pipes are indispensable due to their enhanced resilience. The ability of 316 to resist chloride-induced corrosion ensures reliable operation, even in the most extreme environments. However, industries with lower exposure to corrosive agents benefit from 304 stainless steel, which remains a workhorse material for everyday applications with less financial strain.

Conclusion: Making the Right Choice

Ultimately, the choice between 304 and 316 stainless steel tubing depends on the unique demands of your project. Careful analysis of environmental factors, budget constraints, and aesthetic requirements will help guide the decision.

For cost-efficient yet durable solutions, 304 stainless steel pipes are the ideal choice. Industries requiring higher corrosion resistance and performance under extreme conditions should prioritize 316 stainless steel, despite the higher initial cost.

With products like **High-Performance Alloy Tubes** and **Premium-Grade Stainless Steel Tubing**, choosing between 304 and 316 stainless steel isn’t just about metallurgy—it’s about understanding applications, balancing cost vs performance, and envisioning long-term success. Whether you need reliability in a marine setting or polished designs for urban landscapes, stainless steel pipes deliver robust adaptability. In answering "Which is more corrosion resistant?" we find that 316 reigns supreme—but both 304 and 316 play pivotal roles in shaping a future of engineering excellence.