When renovating a home or designing new furniture, the small details often make the biggest difference in terms of both longevity and daily use. Cabinet hinges, though often hidden, are a critical component that can impact the functionality of your space for years. A common decision-point for homeowners and builders is understanding the difference between 304 and 201 stainless steel hinges. This choice might seem minor, but it is fundamental to ensuring your cabinets withstand their environment and function smoothly over time.

Understanding the Basics of Stainless Steel

Before diving into the specifics of grades 201 and 304, it's helpful to understand what makes stainless steel “stainless.” Stainless steel is an iron alloy that contains a minimum of 10.5% chromium. This chromium is the key ingredient that sets it apart from regular steel. When exposed to oxygen, the chromium forms a thin, invisible, and passive layer of chromium oxide on the surface of the steel. This layer acts as a protective barrier, preventing rust and corrosion. If the surface is scratched, the layer quickly reforms, providing continuous protection. The main distinction between different grades of stainless steel lies in their specific chemical compositions, particularly the varying amounts of elements like nickel and manganese, which significantly affect their performance.

A Closer Look at 201 Stainless Steel

Grade 201 stainless steel is part of a family of austenitic stainless steels where manganese and nitrogen are partially substituted for the more expensive element, nickel. This composition makes it a more cost-effective alternative. In terms of strength, 201 stainless steel is quite robust and offers good impact resistance. However, the trade-off for its lower cost is a significant reduction in corrosion resistance. The lower nickel content makes it more susceptible to rust and pitting, especially when exposed to moisture, humidity, or acidic substances. For this reason, 201 stainless steel hinges are best suited for dry, indoor applications where they are unlikely to encounter water, such as bedroom closets, office furniture, or pantries in arid climates. Using them in a kitchen or bathroom environment is a risk that can lead to premature failure and unsightly rust stains.

The Superior Qualities of 304 Stainless Steel

Grade 304 stainless steel is the most common and versatile type of stainless steel on the market. It is often referred to as 18/8 steel because it typically contains 18% chromium and 8% nickel. This higher concentration of nickel is what gives 304 its exceptional resistance to rust and corrosion. It is highly durable and can withstand exposure to a wide range of atmospheric conditions and corrosive agents. This is why 304 stainless steel is the material of choice for kitchen sinks, food processing equipment, and medical instruments. When it comes to hinges, choosing 304 stainless steel is a wise investment for any cabinet located in a kitchen, bathroom, laundry room, or any area with high humidity. Its ability to resist rust ensures that the hinges will continue to operate smoothly and maintain their appearance for many years.

Key Differences: 304 vs. 201 Hinges Compared

To make an informed decision, it's useful to compare the two materials side-by-side based on the factors that matter most for hardware. The primary question of what is the difference between these materials can be answered by looking at corrosion resistance, where 304 is the undisputed winner. The robust protective layer formed by its high chromium and nickel content makes it ideal for moist environments. In terms of durability, while 201 is slightly harder, it can also be more brittle. Grade 304 offers excellent toughness and ductility, making it more resilient to the repetitive stress of a cabinet door being opened and closed thousands of times. The most significant advantage of 201 is its lower cost, driven by the use of manganese instead of nickel. However, this initial saving can be quickly offset by the need for premature replacement. Finally, while both grades may look identical when new, especially with a polished chrome finish, 201 is more likely to develop rust spots over time, tarnishing the overall look of your cabinetry.

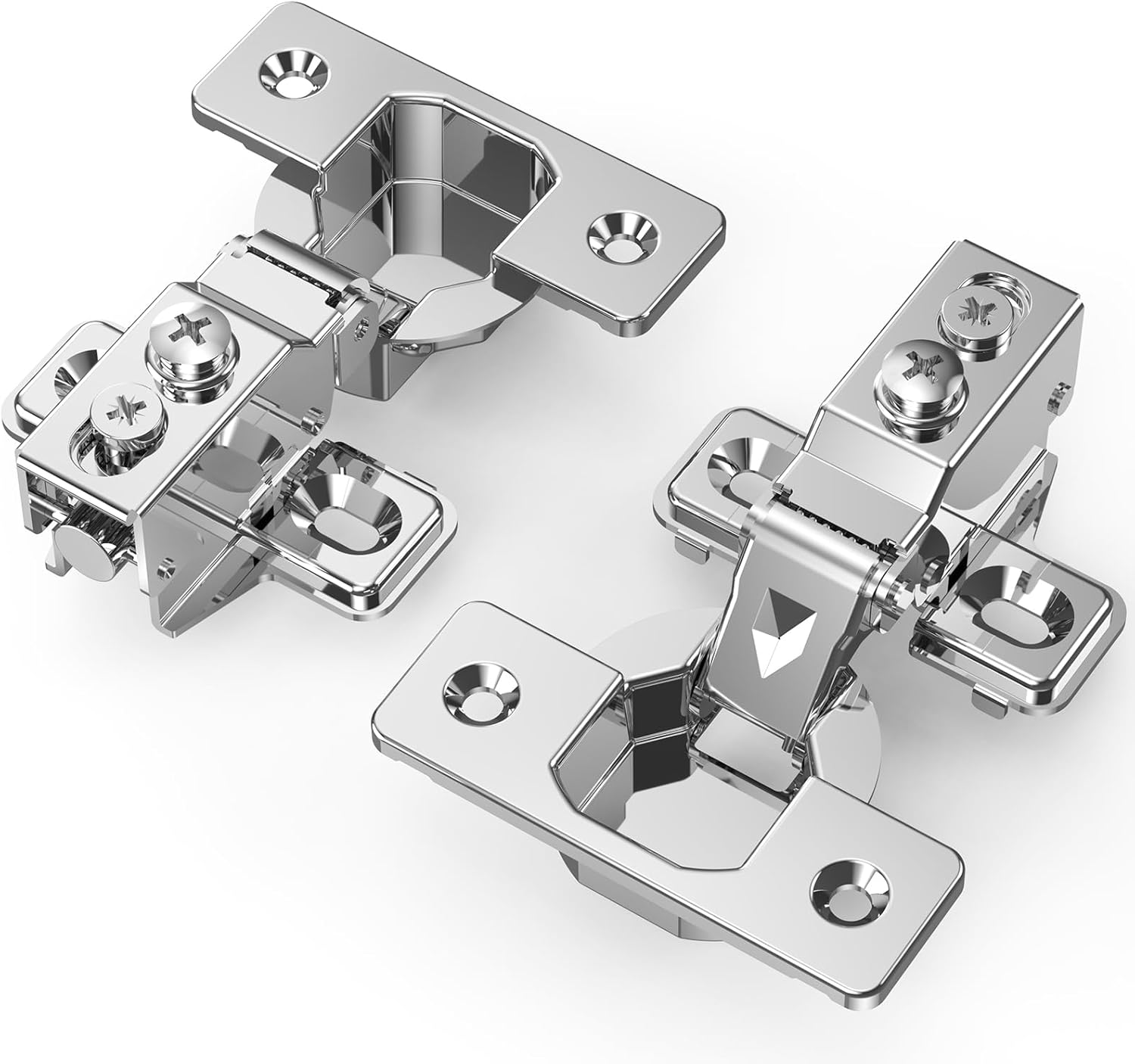

Why Quality Material Matters for Advanced Hinge Features

Modern cabinet hardware is engineered for more than just opening and closing a door. Innovations like soft-close mechanisms, seamless concealed designs, and 3-way adjustment capabilities require a foundation of high-quality material to function correctly long-term. A hinge built from superior 304 stainless steel ensures that the intricate internal components of a soft-close feature are protected from corrosion, which could cause them to seize or fail. Furthermore, a lustrous chrome finish will only maintain its mirror-like shine if the underlying metal is stable and rust-proof. Choosing a robust material like 304 is not just about preventing rust; it’s about guaranteeing that the sophisticated features you invest in, which provide a whisper-quiet closure and flawless door alignment, will continue to add value and elegance to your home for years to come.

Making the Right Choice for Your Cabinets

Ultimately, the choice between 304 and 201 stainless steel hinges depends on the specific application and your long-term goals. For any area in your home exposed to moisture, steam, or frequent cleaning—such as kitchens and bathrooms—investing in 304 stainless steel is the most sensible decision. It provides peace of mind and ensures the longevity of both your hinges and your cabinets. While 201 hinges can be a viable budget option for completely dry areas, the superior performance and lasting value of 304 stainless steel make it the recommended choice for a durable, reliable, and beautiful finish.